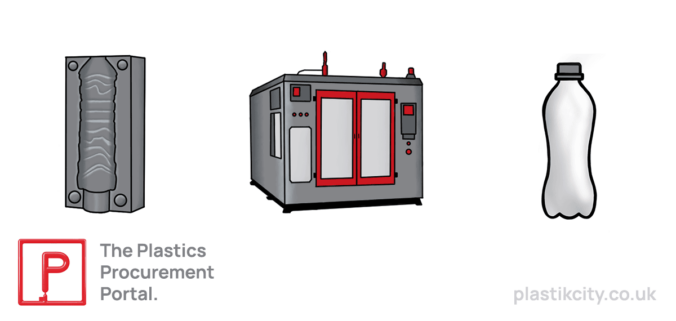

Injection moulding companies are essential in producing high-quality, precise plastic components for industries such as automotive, medical, packaging, and electronics in the country. Many injection moulding companies specialise in creating complex designs with tight tolerances, offering expertise in material selection, mould design, and large-scale production.

Continue reading