For more than 45 years, Hallam Plastics has been providing high quality plastic injection moulding services to blue-chip companies working in the automotive sector.

Increasingly, OEMs and Tier 1 suppliers are having to find new and innovative solutions to meet the ever-changing demands of the sector.

As specialists in automotive injection moulding, we have been able to develop new processes, using specialist polymers to meet these demands.

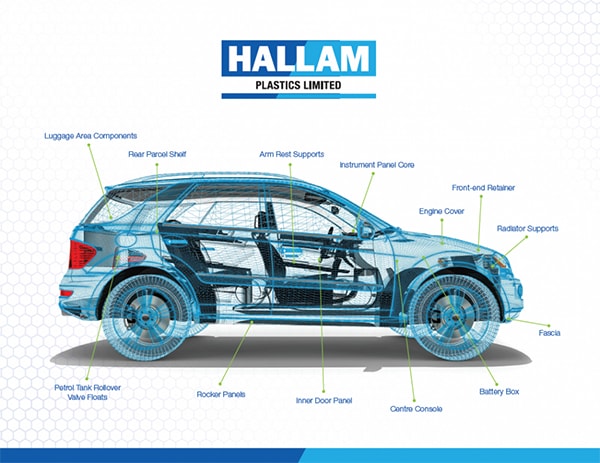

We can produce a wide range of parts and components for the automotive sector using both conventional injection moulding and Engineered Structural Foam (ESF). These include items such as arm rest assemblies, cab interiors, exterior components, engine covers, interior door panels, sunroof shades, dash board insert mouldings, vent assemblies, mud guards, and much more.

ESF is ideal for automotive injection moulding as it offers many advantages that answer industry demands, such as a superior strength to weight ratio. Engineered structural foam has a superior strength-to-weight ratio seven times greater than that of steel and with thirteen times the rigidity of zinc. Therefore, this manufacturing method is often chosen as the perfect, high performance solution for automotive companies where increased strength and reduced weight are key product drivers.

With a strong commitment to providing exceptional customer service, we provide a complete project management service throughout the entire manufacturing process, from design concept and tooling production, through to manufacture and decorative painting.

Our development team has the skill and expertise to help customers with new product development and adapt their existing ones to meet new market demands. We are able to produce small pre-production and prototype runs before entering into full production to ensure that the product is right for the purpose it has been designed.

If you would like to discuss your automotive injection moulding requirements, or have any questions regarding our services, contact us on the below