Fire testing PE cladding has suddenly become a ‘buzz word’ following the tragedy at Grenfell. If there is one material that we come across more often in our modern society this is Polyethylene (PE).

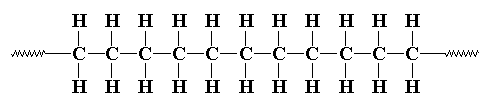

PE is literally the most common plastic in the world and the largest polymer produced globally. Cosmetic bottles, children toys, food packaging, agricultural jerricans, protective hats, insulation materials even bullet-proof vests are PE based. PE is a semi-crystalline polymer and belongs to the family of polyolefins, consisting mainly of ethylene monomers (two carbons and 4 hydrogen) in various molecular weights and architectures. Below is shown the most simple PE linear configuration:

Fire testing PE and why it burns?

Fire testing PE and why it burns?

The main reason why PE is very popular lies on its exceptional material properties combined with low cost production. PE yields very good ductility, impact strength, it is a very good electrical insulator and shows excellent chemical and water resistant properties.

But, PE has one main drawback, this is its performance under high temperatures and/or fire.

PE burns when placed under a source of flame giving off a paraffin odour. What is really important is that after removing the flame source, PE would sustain the flame and keep burning. In fact, in order to understand better the burning properties of PE, think about the candles and how they slowly burn. Candles are actually made of low molecular weight PE!

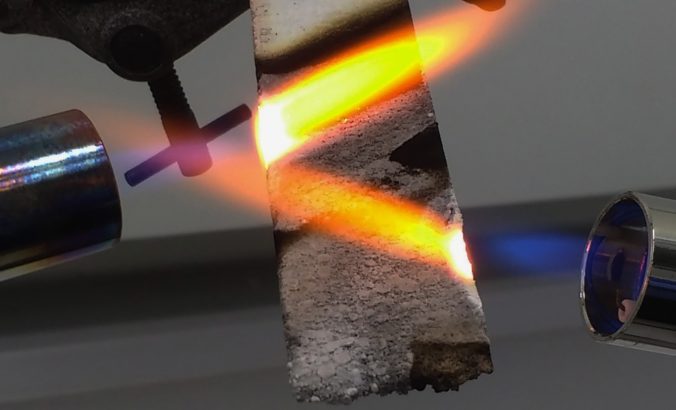

As the PE chain burns, in presence of oxygen, it passes easily up the chain, from one Carbon (C) atom to the other carbon. This means the fire can spread quickly with little to stop it. Fire testing PE panels, such as this short youtube video, shows why the use of PE in cladding is dangerous. Fire testing PE is therefore very important for any designer or architect who is thinking of using the material in their designs.

As a result, it becomes obvious that PE should not be used in large quantities in applications where fire might be an issue, such as in construction or house decoration. Although it cannot initiate fire, it could very well act as fuel for fire.

One way of preventing the spread of fire in plastic is to use flame retardants. These come in different shapes and forms, but a popular way is to use fluropolymers such as PVDF (as shown below). In these polymers a Hydrogen (H) atom is replaced by a Florine (F) atom. As the plastic burns, the reaction with the florine pushes away the oxygen, which in turn kills the flame.

It is the opinion of Impact that the use of PE in any building/construction product which requires flame retardancy is wrong.

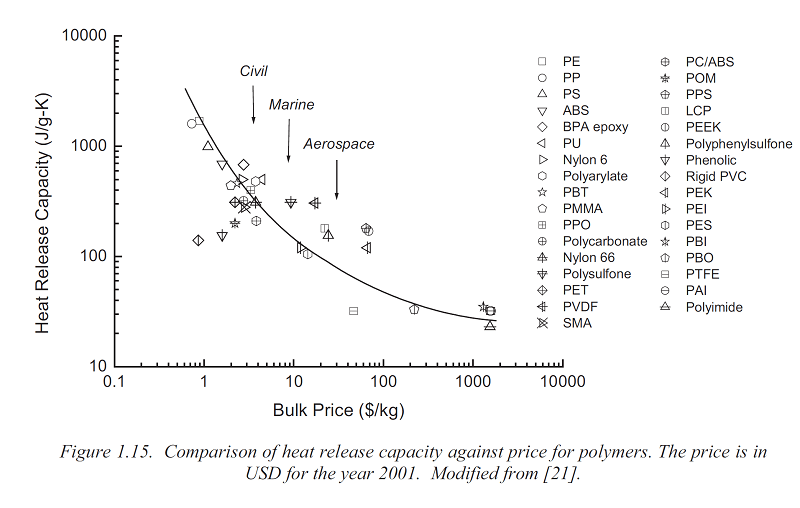

So why was PE used? The figure below shows the pricing of different plastics, against their fire performance. However, PE is also a resilient plastic, with good insulating properties and a wide range of parameters has to be taken into account when designing a product. PVDF is shown above, and while it has better fire properties than PE, it will give off toxic gas when subjected to flame and therefore would also be a poor choice.

Recent material developments have resulted in the productions of two phase composite materials based in Plastics such as PE and minerals. These new materials have showed promising results in fire tests and could be used in construction industries in profiles, doors, panels, insulation and cladding.

For more information on how PE acts in fire, or to test any of your products for fire safety then please get in touch with the Impact Solutions team on 01324 489 182, on email, or via the contact page.

Impact Solutions

Fire testing PE and why it burns?

Fire testing PE and why it burns?