Thousands of homes awoke recently to water shortages, after failed pipework in the water distribution network led to hundreds of leaks throughout the network. Many of these leaks will have occurred where two pipes are joined to together, because of a pipe joint failure.

The blame for the failures was on the freezing weather caused by the #BeastFromTheEast and the effect this has had on the water distribution network. Both ductile iron, and plastic pressure pipes will have been affected.

It is well known that water freezing within pipe work will lead to failures once the water thaws. However, it is less well known that the majority of failures occur within a pipe joint failure, the place where two pipes are joined together. This is because this is frequently the weakest point of any pipeline installation.

The plastic pipes themselves are tested extensively for hoop stress, using both c-ring tests and hydrostatic pipe tests which qualify the pipe material to either PE80 or PE100 (with the number being the MPa the pipe will hold after 50 years of use. However, the pipe joints themselves are frequently not tested, which can lead to premature pipe joint failure, especially in harsh conditions.

Plastic pipes are joined using one of two methods – either Butt fusion, or, as we will focus on here, electrofusion. While both methods are susceptible to pipe joint failure under freezing conditions, electrofusion welds are especially problematic. A report from the Water Industry in 2012 determined that as many of 20% of all electrofusion joints would fail prematurely.

This is because electrofusion welds are sensitive to welding conditions. Any failure in the jointing process can lead to a premature pipe joint failure at a later date, especially under adverse conditions, such as ground movement, or pressures within the pipe. A guide to electrofusion welds can be read here.

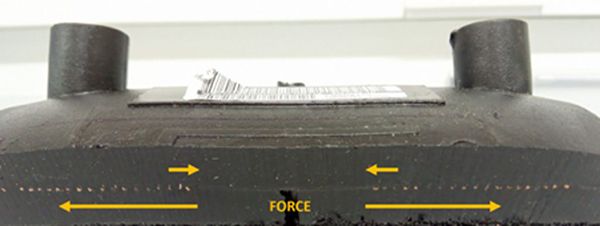

When a pipeline freezes it causes forces in two directions. Firstly, the water expands and pushes the pipe outwards. This force is called the “hoop stress”. The second force on the pipe will be a shrinking effect of the plastic itself along the length of the pipe. This will pull the pipe from where it is fixed, or jointed at either end, as shown in the figure below. In addition to this force, the coupler itself will also be shrinking, and exerting a force in the opposite direction, placing even more pressure on the joint (in the figure below the “joint” is across the area with the copper pins). The diagram below shows these forces.

A well made PE joint will be ductile. This allows the plastic to stretch under load without cracks or failures. A poorly made PE joint however will fail in a brittle manner, causing cracks and failed pipe lines.

Quality control of pipeline installations should incorporate strict procedures, non destructive testing and destructive testing of sample fittings to ensure procedures are being followed. These quality protocols can ensure that a plastic pipeline can avoid failures during extreme conditions or extreme weather events, ensuring no plastic pipe joint failures.