In this blog, RJG Technologies, a company offering injection moulding process support, training, and consultancy services, examines what effects the second stage speed setting has on your specific pressure curves as well as the part weight at different volumetric speeds.

Hold speed or hold velocity? How many machines today have it and what does it do to your process?

The machine controller input of hold velocity started to become more and more prevalent with the onset of electrically driven moulding machines. The setting tells the machine how fast to move the screw during the second stage. But, and this is a big but, the second stage is a pressure-limited portion of our process. You can’t have velocity control on a pressure limited portion of a process. So how effective is the speed setting then?

The moulding machine will use the speed that is input into the machine controller only until the set second stage pressure has been reached. Once your second stage pressure is reached, you will notice that the screw slows down and may even eventually stop. We look at this velocity input as a matter of response time. The setting tells the machine controller how fast you want to get to the second stage pressure setting.

So the question becomes, “Does this setting impact my process?” The answer to that question is simple: Yes. Below you will find a couple of graphs that represent first, the injection pressure profile and secondly, the part weight. These are correlated to seven different second stage velocities starting at 5ccm/s up to 35ccm/s moving in 5ccm/s increments.

In figure 1, you will see that the slowest speed is represented in orange. It shows a large droop in the injection pressure profile after the transfer has been reached. This occurs because the cavity is short at transfer, and it takes a period of time before the cavity completely fills and starts to pressurise. The resistance in the cavity is now pushing back on the screw, and the second stage pressure setting is reached and stabilised. As the second stage velocity is increased, you will notice that the droop gets smaller and smaller, and the time it takes to reach the second stage pressure setpoint gets shorter and shorter.

Figure 1: Second Stage Speed vs. Machine Response

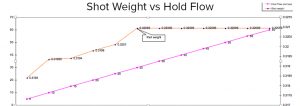

In figure 2, part weight is plotted against the second stage speed setting. You will notice that the part weight is continuing to rise until 30ccm/s is reached. You will also notice that at this time, any additional second stage speed has no influence on the part weight. This is the sweet spot for where the setting should be set—at a point where the final part weight is no longer influenced by the second stage speed.

Figure 2: Second Stage Speed vs. Part Weight

Remember to think about what is happening to the plastic and to your parts during this time. This is one of the most influential periods of your process for setting dimensions on the part. The slower the speed and response are, the slower you are packing out the parts and allowing the material to cool and solidify.

What about other machines?

If you are like most moulders who are scheduling a mould in several different moulding machines, it will be important to understand how each of those machines reacts to the second stage speed setting. Just because 30ccm/s works on machine four doesn’t mean that you will get the same response on machine 12. This could be due to different machine makes and models, ages of the machines, hydraulic vs. electric machines, you name it. There are too many things to list that could contribute to the difference.

You may also have machines that don’t have an input for second stage velocity. There are many machines out there that don’t. In this case, the moulding machine will typically use the last fill speed input on the machine controller. If that setting is slow, then the second stage velocity will also be slow.

Other influences

Besides the second stage speed setting, the size of the fill-only part can also contribute to the droop or slow response. If the fill-only part is 60% full at transfer instead of 98% full at transfer, then it will take more time for the cavity to fill out and pressurise. When conducting this study, we want to make sure that the parts are 98% full at transfer to eliminate that as a potential cause in the response. We want to make sure that we only measure the influence of the second stage speed velocity on the process.

At the end of the day, we are trying to produce the most repeatable parts in the fastest, most repeatable time, and the second stage speed setting is an often-overlooked influence on the process. Knowing how your machines respond to this input is one more step toward being better than the next moulder.