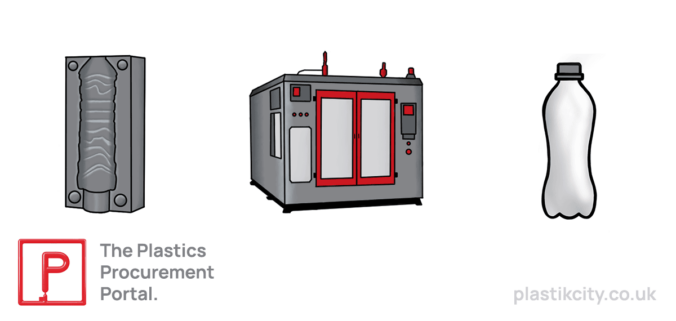

Blow moulding is a widely used plastic manufacturing process in the British and Irish plastics industry. This method involves heating plastic until it becomes pliable, then inflating it inside a mould to create hollow parts. Blow moulding is commonly used to produce items such as plastic bottles, containers, and tanks for sectors like packaging, automotive, and household goods.

Its versatility and efficiency make blow moulding a popular choice for manufacturing lightweight, durable plastic products with uniform wall thickness. This process is ideal for high-volume production and can be customised to create a range of shapes and sizes, offering cost-effective solutions for complex plastic components.

Continue reading