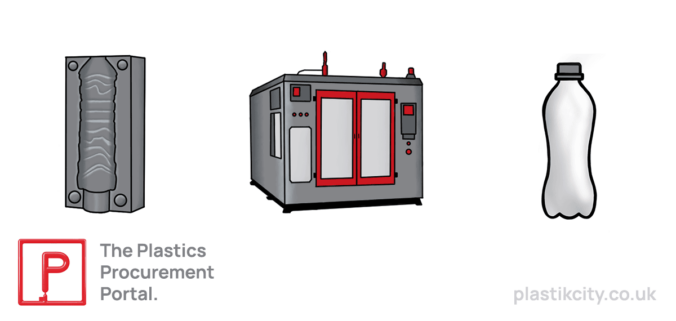

Blow moulding is a widely used plastic manufacturing process in the British and Irish plastics industry. This method involves heating plastic until it becomes pliable, then inflating it inside a mould to create hollow parts. Blow moulding is commonly used to produce items such as plastic bottles, containers, and tanks for sectors like packaging, automotive, and household goods.

Its versatility and efficiency make blow moulding a popular choice for manufacturing lightweight, durable plastic products with uniform wall thickness. This process is ideal for high-volume production and can be customised to create a range of shapes and sizes, offering cost-effective solutions for complex plastic components.

Choosing the right blow moulding company is essential to achieve precise moulding, expert material selection, and strict quality control. A skilled blow moulding company can offer tailored solutions for complex designs, ensure consistent product standards, and deliver efficient production timelines—all critical for meeting quality and cost expectations in high-volume manufacturing.

With blow moulding’s ability to work with a range of thermoplastics, including Polyethylene (HDPE, LDPE), Polyethylene Terephthalate (PET), Polypropylene (PP), and Polyvinyl Chloride (PVC) partnering with an experienced blow moulding manufacturer can significantly enhance production efficiency. This collaboration ensures consistent, high-quality results that are customised to your specific needs, helping to streamline operations and improve overall product performance.

The top two rating is the view of the team at leading plastics industry resource, PlastikCity. All companies have been verified as follows:

- Supply premium-quality equipment

- Established a minimum of two years

- Provide UK-based, reputable service support

- Financially sound

Interested in finding injection moulding companies? Visit PlastikCity.co.uk to quickly and easily request quotes from our top manufacturers.

In alphabetical order:

Mergon

Lancashire

Mergon is a leading blow moulding manufacturer specialising in technical parts for the automotive, healthcare, industrial, and leisure sectors. Established over 40 years ago, the company now boasts 23 machines handling capacities from 1L to 500L, the company offers comprehensive services, including design, tooling, packaging, and finishing. Mergon operates 24/7, using materials like HDPE, PP, and EVA, ensuring high-quality, tailored blow moulding solutions.

The Plastek Group

Nottinghamshire

The Plastek Group is a leading blow moulding and injection moulding company in the plastic packaging industry, specialising in innovative solutions for sectors like personal care, household, food & beverage, and pharmaceuticals. With 48 moulding machines, including injection blow moulding capabilities, The Plastek Group offers full-service support from design to production, ensuring high-quality, sustainable packaging solutions.

Supporting Information

Blow moulding is a popular manufacturing process used to create hollow plastic parts by inflating heated plastic into a mould. This technique is ideal for producing containers and other hollow items, making it essential in industries that require lightweight, durable, and high-quality plastic products. The process involves heating plastic until it becomes pliable, then inflating the plastic within a mould, forming the desired shape.

There are different types of blow moulding methods, including extrusion, injection, and stretch. Each method has unique benefits, with extrusion typically used for making bottles and tanks, while injection is suited to producing high-quality, precise items like medical bottles and cosmetic containers. Stretch, on the other hand, is commonly used for creating PET bottles, especially for beverages, due to its ability to create strong, lightweight products.

The applications of this process span multiple industries, from automotive and household goods to packaging and pharmaceuticals. Its flexibility and efficiency make it a preferred choice for manufacturers aiming to produce high-volume, consistent, and cost-effective plastic products that meet industry standards.