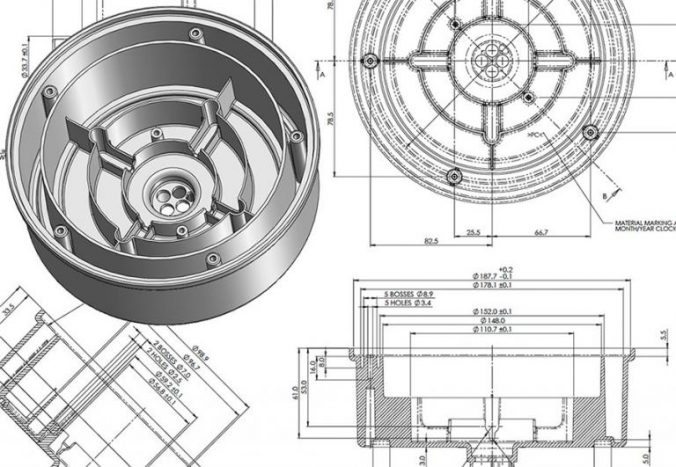

3D CAD data is the gateway to exciting and transformative technologies such as simulation, 3d printing and CNC machining.

CAD data is the output of the design and development process and needs to include all the geometry to fulfil the requirements of the product in all aspects. This includes not only the functional form and performance criteria but also the manufacturability, assembly, colour, finish, material, sustainability and cost, to name a few.

What do we need to create CAD data?

The information to create new CAD data (and a new design) can come from a multitude of media and can include sketches, mind maps, engineering drawings, physical parts or existing CAD models; anything that communicates the concept and features that need to be included.

As the design progresses, more detail is added to reflect the requirements of the product. Once form and function are established, manufacturability, assembly and performance requirements can be included, the aim being that when the prototype is built, all the future issues have been considered and approved.

The development of the data during the design phase is vital, as not only does it define the product, but it also facilitates all the subsequent manufacturing. From this, we can translate your idea into a product. We can design to suit the manufacturing process and manage the entire manufacturing cycle if required.

Which CAD software do we use?

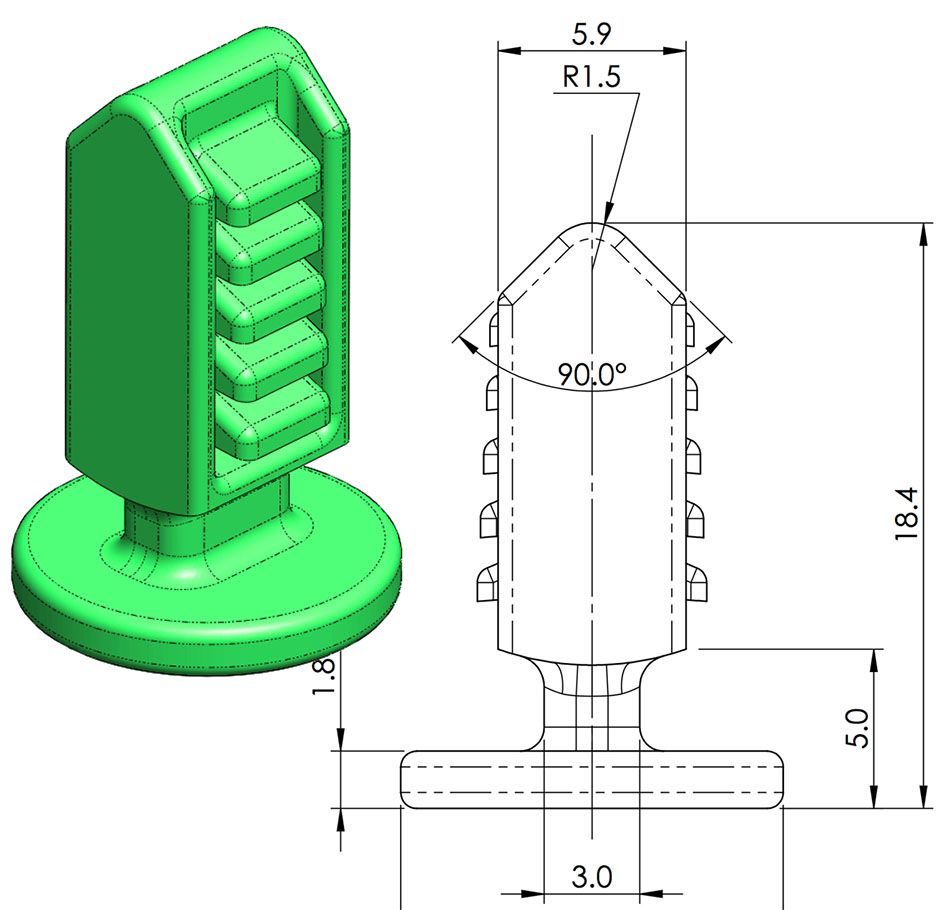

At Plunkett Associates, we have elected to run Solidworks as our primary 3D modelling package and then augment this with specialist software as required.

We currently have two seats including Solidworks Premium, one seat of Solidworks Simulation Professional and Moldflow for injection moulding analysis. As such, we can work with 3D models to analyse their strength, not just at the component level but also the assembly level.

Manufacturing parts that perform as intended, quickly and to specification has always been crucial to our customers. Producing a part that performs first time without the need for multiple iterations or physical testing is now becoming equally important. Having the design data in a system such as Solidworks facilitates various analysis options without having to resort to a physical prototype.

We work with you at all times (this is not a “hands-off” exercise), to build on your existing knowledge, and create a product that meets your expectations and that we are confident can be manufactured in the specified volumes.

Ultimately we aim to develop and enhance your idea, providing support and advice wherever we can. So why not give us a call?